Projects – MARNAY Energie

Projects – MARNAY Energie

Background and history of the MARNAY Energy biogas unit

Mr. BREUSSE took over, in 2001, the family grain farm (450 acres) on the site of Marnay Mill Farm, 15 km south of Sancerre. In 2006, he established an environmental diagnosis with the Cher Chamber of Agriculture and undertook the limitation of mineral fertilization use and the reduction of energy costs and greenhouse gas emissions.

Located in an area facing problems processing wine and agricultural waste, anaerobic digestion emerged as the most appropriate solution for him and for the community.

Services provided by LEDJO Energie

- Field study

- Feasibility Study

- Administrative procedures: Building permits, electricity connection procedures, etc.

-

Exceptionally: General construction and project management / Stakeholder management

- Consulting construction companies

- Implementation and Support of construction contracts

- Operating studies validation

- Managing the proper execution of construction contracts

The project leader’s objectives

- Contribute to sustain local sectors of livestock, food (AOC Crottin de Chavignol) and viticulture (AOC Sancerre) by recycling problematic organic waste.

- Producing organic fertilizers that can replace mineral fertilizers

- Reduce energy costs and diversify his revenue

- Help preserve sensitive wetlands on the upstream side of the Loire

Benefits for the community

MARNAY Energy is a territorial intelligence project in that it brings together local actors and waste within a 20 km radius. The site deals in particular with wine effluents (marc and Sancerre stillage), by-products of cheese production (whey Crottins of Chavignol) and cattle and goat manure. The project helps to perpetuate these local sectors weakened by the costs and treatment obligations of their waste while reducing pollution.

Biogas and thermal recycling

Biogas is recovered in a cogeneration unit with a capacity of 1 067kWel.

The electricity is fed into the network.

The cogeneration heat is used, in part, to maintain the temperature of digestion. The remaining heat is used throughout the year to dry the digestate and a part of the year, to pre- dry the corn and reduce the consumption of propanein the Marnay Mill farm with in the long run an evolution towards the drying timber (platelets).

The resulting energy efficiency of the processes involved is about 72 % as calculated according to the May 19 2011 Decree (fixing the purchase conditions of electricity produced by the facilities that enhance biogas)

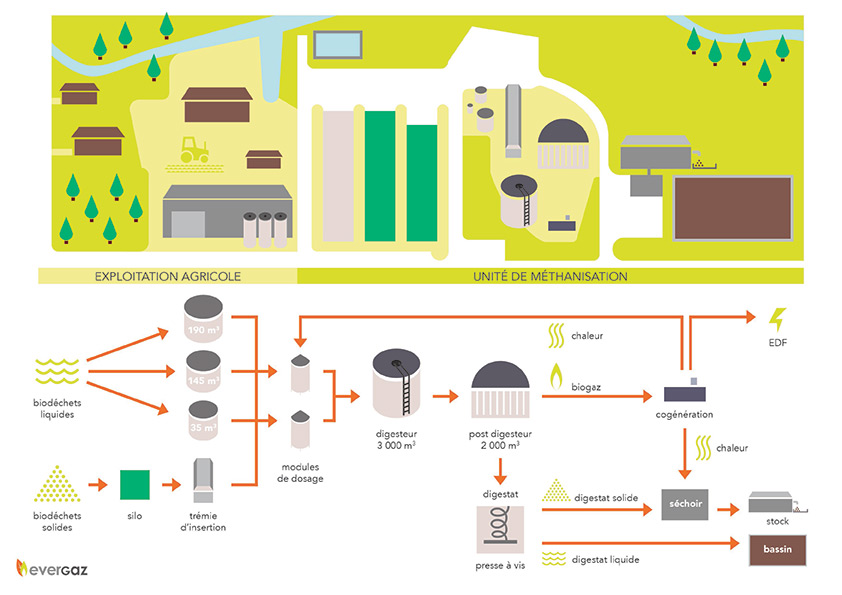

Site map

Energetic performance of the unit

Biogas production: 3,450,000 Nm3 / year

ELECTRICITY

- Electrical power: 1067 kWel

- Marketable production: 8121 MWh / year

HEAT

- Thermal power: 1097 kWth

- Gross heat production: 8428 MWh / year

- Consumption: 2331 MWh / year

- Usable production: 5756 MWh / year

Environmental impact

Each year MARNAY Energy will avoid the emission of 3,589 tonnes of CO2 (carbon footprint conducted in December 2011 with the DIGES V2 ADEME tool)